| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : JBETEP

Model Number : TE-300

Certification : Ex I CE

Place of Origin : chongqing,CHINA

MOQ : 1 set

Price : 3855-55587 USD

Payment Terms : T/T

Supply Ability : 300 sets

Delivery Time : 7-15working days

Packaging Details : Wooden box (vacuum packaging optional)

Feed capacity : 300 Solvent Distillation Machine

Recovery rate : 95%

Maximum heating power : 16KW

Mains : 380V 50/60Hz

Processing time : Average 5 hours

Daily processing capacity : Estimated 600L-800L

JBETEP Explosion-Proof Dual-System Solvent Recovery Machine For Printing & Electronic &Spraying

Product

Dual-reactor, dual-system solvent recovery machine: production capacity adjustable on demand.

Dual/single mode selection, the amount of waste liquid processed fluctuates according to the order schedule.

Intelligent and labor-saving, no need to set up dedicated positions

The system can be freely selected in "dual/single mode" to automatically complete temperature control, abnormal alarms, and automatic shutdown, without requiring dedicated personnel to monitor the entire process—eliminating the need for a separate dedicated position and saving manpower.

Structural composition

Dual-reactor solvent recovery unit: The core consists of two distillation vessels connected in series or working in tandem, along with two corresponding heating and condensation systems, and a pipeline and valve control system connecting the two vessels. The two vessels can operate in conjunction with each other or independently. For the same processing capacity, it offers faster speed and higher efficiency.Customized solutions are suitable for all scenarios of chemical spraying waste solvent recycling, improving efficiency and reducing costs without compromise, making industrial production more stable and worry-free!

Which companies do solvent recovery machines solve problems for?

| Industry Sectors | Specific Application Scenarios / Descriptions |

| Industrial manufacturing | Automotive parts, hardware manufacturing, precision casting, plastic products, FRP (fiberglass reinforced plastic) products, etc. Mainly used for parts cleaning, degreasing, and steam degreasing. |

| Surface treatment and coating | Electroplating, spraying, painting and coating, powder coating. Recycling of thinners, gun cleaning solutions, etc. used in spraying and painting processes. |

| Chemicals and pesticides | Chemical plants and agricultural chemicals. Chemical production involves a large user of solvents, resulting in significant recycling needs. |

| Electronics and High Technology | Electronic products, LED products, LCD optical products, and digital products. Solvents such as isopropanol and * are commonly used in the cleaning and manufacturing processes. |

| Pharmaceuticals and Medical Devices | Pharmaceutical industry and medical device manufacturing. High purity requirements are placed on solvents, and recycling and reuse must ensure compliance with standards. |

| Printing and Packaging | The printing industry. Solvents such as ethyl acetate are used extensively in printing and laminating processes. |

What value does a solvent recovery machine create for production?

1. Reduce Production Costs

(1) Solvent Recycling: Organic solvents (such as xylene and *) volatilized during the painting process can be recycled, purified, and reused, reducing the amount of new solvents purchased and directly saving raw material costs.

(2) Reduce Hazardous Waste Disposal Costs: Recycled solvents can replace some new solvents, reducing the amount of waste solvents to be disposed of and avoiding high hazardous waste disposal costs (such as transportation and incineration).

2. Enhanced Environmental Compliance

(1) Reduced VOC emissions and lower risk of environmental penalties.

(2) Meeting carbon reduction requirements: Reducing carbon emissions in the production process through solvent recovery helps companies achieve their environmental goals and enhance their green image.

3. Improve Workplace Safety

(1) Reduce Explosion Risk: High concentrations of solvent vapors in paint spraying workshops can easily lead to combustion and explosion. The recovery machine reduces vapor accumulation through closed-loop circulation, improving explosion-proof safety.

(2) Improve Working Environment: Reduces the concentration of irritating odors and toxic gases in the workshop, protecting worker health and lowering the probability of occupational diseases.

4. Optimize Production Efficiency

(1) Stable Supply of Recycled Solvents: Recycled solvents can be directly used to dilute paint or clean equipment, reducing the risk of production stoppages due to solvent shortages.

(2) Automated Operation: Modern solvent recovery machines can be integrated into the painting line to automatically collect, distill, and purify solvents, reducing manual intervention.

5. High long-term return on investment

(1) Fast return on investment: Although the initial investment is high, the cost can usually be recovered in 1-3 years by saving solvent costs and hazardous waste treatment fees (depending on the amount of solvent used).

6. Technical Adaptability

(1) Compatible with Multiple Solvents: Recovery parameters can be adjusted for solvents with different boiling points (such as alcohols and esters) to meet the diverse needs of spray coating chemicals.

(2) Modular Design: Small mobile or large centralized recovery systems can be selected according to the workshop size to flexibly adapt to the production layout.

Craftsmanship details------Polished with care

Windows-----The inside of the vessel can be monitored in real time through the viewing window during the processing of dirty solvent.

Serve:

Let the solvent be recycled, focusing on providing customers with safer and higher-quality solvent recovery equipment, helping enterprises save energy and reduce emissions!

As a professional [solvent recovery machine] manufacturer, we provide customers with one-stop services such as consulting, solution design, solution implementation, equipment delivery, personnel training, and after-sales service.

Pre-sale Service:

--24 Hours online service for your consultation.

--Help choose right model, and a series of services, people, and advice.

--Give you the best offer.

--Provide discount for many sets order.

--Do customer's request.

--Choose payment term you convenient.

--Promptly production and delivery, inform you in time.

--Can provide invoice value as you like to decrease your tax.

After-sales service:

-- One-year warranty, lifelong technical support.

-- Overseas training for technical engineers can be provided.

-- Remote control technical consultation is provided.

-- Maintenance plan is provided.

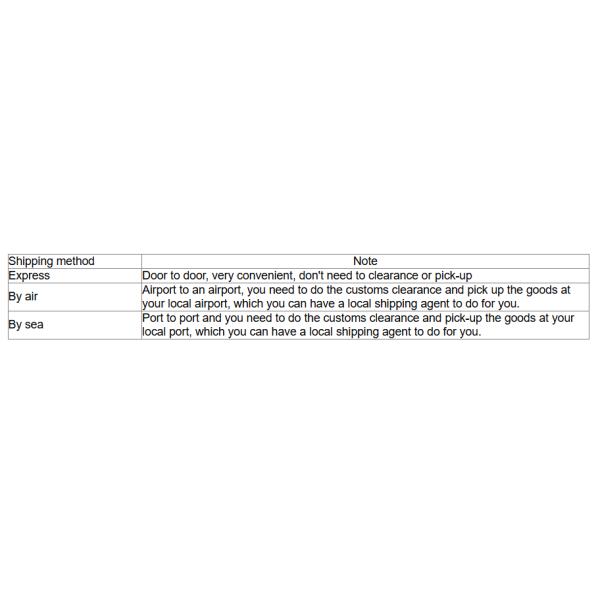

Transportation:

- WELCOME TO CHOOSE US-

We will choose the safest and most economical mode of

transportation to ensure the safe arrival of the goods

|

|

JBETEP Explosion-Proof Dual-System Solvent Recovery Machine For Printing & Electronic &Spraying Images |